Container handling machines

A-1Marine provides specialized service for container handling machines, whether they are top picks, reach stackers or empty handlers. We take care of all makes and models, and can do custom fabrication. We have expertise in several key areas:

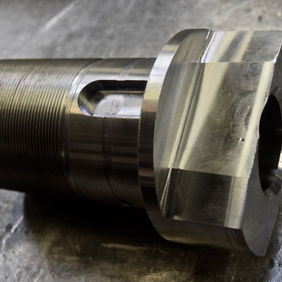

Twist lock pins

-

For many years, A-1 Marine has manufactured twist lock pins for machines at container terminals and off-dock operations.

-

We keep hundreds of pins in stock, ready to go.

-

There is a large number of different pin sizes and configurations for the many models of machines in use, often with variations for the same model from year to year.

-

We manufacture our pins on a C&C lathe in our dedicated machine shop, ensuring quality and accuracy.

-

All twist lock pins are made from 4340 HTSR (heat treated, stress relieved) steel, which yields the highest possible quality pins available anywhere.

-

We supply each pin with a Transport Canada approved certificate, and we maintain traceability back to the original mill certification.

-

We offer testing and certification for all models of twist lock pins, and can renew or refurbish pins with minor deficiencies.

-

A-1 can also manufacture guide blocks, guide block rings and other related items.

-

Contact us now for a quotation.

Bearings

Bearings take a beating during the normal operation of container handling devices and require replacement on a regular basis.

-

Options for replacement are either OEM or after-market parts.

-

For the sake of quality control, many terminal operations require original manufacturers' parts, which can be very expensive, due to a significant number of middle men.

-

For Terex / Fantuzzi machines, A-1 now purchases direct from the manufacturer in Italy, thereby saving considerable cost to the customer.

-

We will keep a stock of bearings for committed customers.

-

For more information or a quotation, please contact us.

Major mast rebuilds

The masts of container handling machines are very large structures that are subject to considerable stress during regular operations. They can sustain damages such as cracks and twisting, which are beyond the scope of most heavy equipment shops. This is where A-1 Marine comes in.

-

strip down the mast, clean off grease

-

determine the extent of damages

-

recommend a course of action, complete with costing

-

expert welding of cracks, addition of doubler plates if necessary

-

rebuild of the mast with refurbishment of all attached items

-

replacement of twist lock pins and guide blocks as required

-

complete certification of the final assembly